In recent years, with the continuous development of materials and Engineering Science and technology, all kinds of new materials emerge one after another, and the composite materials are widely used in civil engineering because of their excellent performance. Carbon fiber reinforced polymer (CFRP) is a kind of new material, which is made of carbon fiber as the reinforcement material and the composite resin. Micro anti slide pile material for fine stone concrete or cement mortar (sand), through the infusion pressure perfusion method. Anti slide pile with large volume and general reinforcement, excessive weight has definite restrictions on the use of the environment, while the micro anti slide pile to avoid such a situation, be flexible and adaptable to various environments, and can be used singly or in bundles, reinforcement selection can be defined by the force of demand. With the emerge in an endless stream of new materials, micro pile material also gradually began to diversify, combined with the advantages and characteristics of carbon fiber composite materials, applied micro anti slide pile structure, to improve the performance of anti slide pile and horizontal effect is obvious.

1, carbon fiber and Its Composites

1.1, carbon fiber

There are many kinds of carbon fiber materials, the carbon content is above 90%, and the different types of carbon content. The utility model is characterized in that the high carbon content artificial fiber without melting is stabilized by high temperature treatment, and then is processed by graphitization and carbonization processing technology. The carbon fiber material has the characteristics which are not possessed by the common carbon materials, such as flexibility and anisotropy, and shows high strength and specific strength.

1.2, carbon fiber composite

Can the collective material and carbon fiber composite processing variety, epoxy resin is one of the products of carbon fiber reinforced epoxy composites (CFRP) have excellent specific strength and modulus of composite indicator is widely used on the strength, stiffness, fatigue, weight and other demanding fields of engineering, 1. The excellent properties of CFRP include: small density, light weight, high strength, fatigue resistance, high temperature resistance, corrosion resistance, strong shock resistance and easy forming.

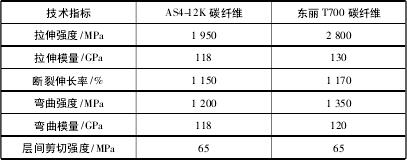

At present, the domestic CFRP has not been extended to the field of civil engineering. The main mechanical properties of common carbon fiber composites are shown in table 1.

Table 1 main mechanical properties of carbon fiber composites

2, micro pile and carbon fiber composite material pile key calculation theory

2.1, the definition of micro pile

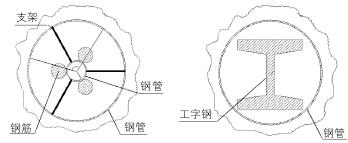

The utility model relates to a mini pile, which belongs to the form of an anti slide pile supporting type. The utility model is divided into an independent micro pile, a connecting beam micro pile, a pile cap and pile foundation according to the structural combination mode. Diameter is generally between 100 mm ~ 300 mm, slenderness ratio greater than 30. The pile body material by pressure type cement slurry composition (sand), concrete, steel and composite materials, according to the requirement of the stress, the tectonic framework can be reinforced, steel pipe, steel, high-strength steel, carbon fiber or glass fiber reinforced, as shown in Figure 1 - 5.

? 1 ??????

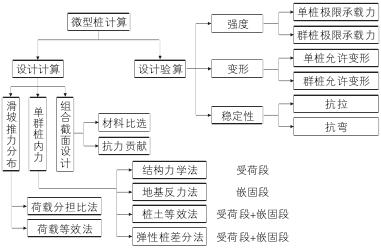

2.2, carbon fiber composite material pile design calculation

Carbon fiber composite material micro pile belongs to micro pile, only the selection of materials added carbon fiber composite material to replace all or part of the reinforcement, different material parameters, the stress analysis principle and the design process with ordinary micro anti slide pile with the same reference, the general anti slide pile design framework. The design technology of carbon fiber micro pile reinforcement of landslide, see figure 2.

? 2 ???????????

3. The contribution of different materials to the internal force of the system

The anti bending ability of the anti slide pile is small, so it is necessary to consider not only the use of the pile group, but also some additional materials in the steel pipe to increase the flexural and tensile bearing capacity. The problems are as follows: it is not obvious to improve the bearing capacity of the material; the installation is more complex, especially in the slope. Therefore, the carbon fiber reinforcement (7) is introduced, and the calculation and comparative analysis are carried out.

According to the equivalent steel ratio, the steel tube and steel composite structure can be calculated according to the equivalent stiffness method or equivalent steel ratio. In view of the fiber reinforcement, because the modulus is smaller than the ordinary steel bar, and the tensile strength is the multiple relations of ordinary steel bars, the calculation of the equivalent stiffness method should be taken into account. It is assumed that the diameter of the steel pipe pile is 150 mm, the diameter of the steel pipe is mm and the wall thickness is 4 mm.

3.1, steel tube and concrete combination

Select the unit pile length is 1 m, the cantilever beam structure under uniform load, according to the equivalent stiffness method to calculate the ultimate bending moment is 21.139 kN - m, according to the equivalent concrete filled steel ratio calculation method was 21.159 kN / m, the results are basically the same. However, the structure is simple beam can be 50.734 kN * m, the results do not match. It is concluded that the equivalent stiffness of the back calculation moment is affected by the distribution of the structure and the load form, which is not as accurate as the equivalent steel bearing rate method.

3.2, the combination of concrete filled steel tube and built-in

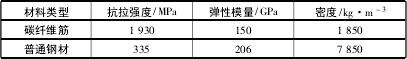

Built in steel tube concrete other materials usually material combination method for the project, which is the most common built-in HRB335 reinforced steel I-beam, and other times. Based on the success of research and development of new materials and engineering practice, the introduction of carbon fiber reinforcement. The carbon fiber reinforced bar has the advantages of high strength and low density, which can not only improve the resistance of the pile body, but also bring great convenience to the construction. The physical and mechanical properties of the two materials are compared as shown in table 2.

? 2 ??????

3.3, ordinary steel pipe combination

According to the equivalent combination of ordinary reinforced steel ratio to calculate, without considering over reinforcement, analysis of 3 root diameter and diameter of 25, with 22, 28, 32 with four kinds of circumstances, the combination of four kinds of steel ratio were 0.1607, 0.1867, 0.2172, 0.2666; the ultimate moment is: 41.018 kN m, 47.687 kN m kN, 55.709 m, 69.009 kN - M.

3.4, steel composite pipe

In this paper, two kinds of methods are used to calculate the character of steel pipe. The commonly used 10 I-beam steel pipe diameter is 133 mm, the wall thickness is 5 mm, the other parameters do not change. According to the equivalent stiffness calculation was not the ultimate moment when machining steel is 22.593 kN - m, adding 32.687 kN after the I-beam ultimate moment of M, according to the equivalent steel ratio were 16.850 kN and 38.946 kN - M - M.

3.5, steel tube carbon fiber reinforced composite

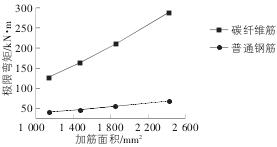

The built-in carbon fiber reinforced steel pipe pile by the equivalent calculation method with reinforcement ratio, calculation of steel fiber reinforced other processing, will be equivalent to the reinforcement ratio, relative steel tube carbon fiber reinforcement belongs to high strength materials were added for equivalent calculation of ultimate moment. Analysis of 3 root diameter and diameter of 25, with 22, 28, 32 with four kinds of circumstances, the ultimate moment is: 127.070 kN m, 164.714 kN, 210.730 m, kN, m, kN 287.930 m, the built-in carbon fiber is 3 times to 4 times the ordinary reinforced ultimate moment, see figure 3.

? 3 ????????

4, conclusion

According to the characteristics of carbon fiber composite material and its innovative application in the construction of micro anti slide pile, the following conclusions are summarized:

1) carbon fiber composite material with low density, high strength, good fatigue resistance, high temperature resistance, corrosion resistance, shock resistance and damage characteristics of high security and easy forming process, is a kind of advanced composite materials can be widely used in civil engineering.

2. Because of the material defects, the traditional steel reinforced concrete anti slide piles are prone to corrosion of steel bars and cement cracking, which will affect the anti sliding effect. The use of carbon fiber reinforced concrete and the whole or part of the steel bars in place of carbon fiber reinforcement can reduce this kind of disease, prolong the service life of the anti slide pile and improve its anti sliding effect.

3) on the micro pile built in material analysis, carbon fiber reinforcement can be built-in resistance increased by about 4 times, and the tensile strength of CFRP tendons is about 9 times more reinforced, meet the anchor effect, so it is worthy of popularization and application.

Reference:

Chen J h. application of carbon fiber composite materials [J]. Development guide, 2012 (6): 20-21. ()

Li Wei. Application of carbon fiber composite materials in aerospace field [J]. Chinese optics, 2011 (6): 201-212. (in Chinese)

Ding Yalin, Tian Haiying. A structural technique to improve the application performance of carbon fiber reinforced polymer (J). Optical precision engineering, 2003, 11 (): 287-290.

4 weeks Xianyan. Carbon fiber composite materials in civil engineering application J. Journal of Central South University of Forestry and Technology, 2007 (10): 26-32.

Sun Shuwei, Zhu Benzhen. A method for the design of reinforced soil slope with micro pile group based on the ultimate resistance analysis [J]. Chinese Journal of geotechnical engineering, 2010, 11 (): 1671-1677.

Su Yuanyuan, Zhang Zhanmin. Review and Discussion on the design and calculation method of micro anti slide piles [J]. Chinese Journal of geotechnical engineering, 2010, 7 (): 222-228.

Wang Chengzhong. Research and development of carbon fiber reinforced polymer (J). Construction technology, 2005 (7): 37-39. (in Chinese)