I. overview

Bashang 2X250kN two-way door open close machine installed on the maintenance platform hydropower station 470.60m, outdoor work, rail surface elevation is also 470.60m. The door machine through the trash rack and rod operation power plant overhaul gate, through mechanical automatic grabbing beam operation of spillway gate, door machine is fast lifting equipment and maintenance gate hoist.

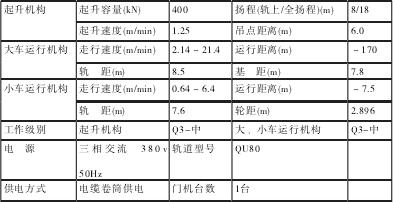

The main technical parameters of two way gate hoist are as follows

Two, the installation of construction procedures and methods

1, the overall installation steps

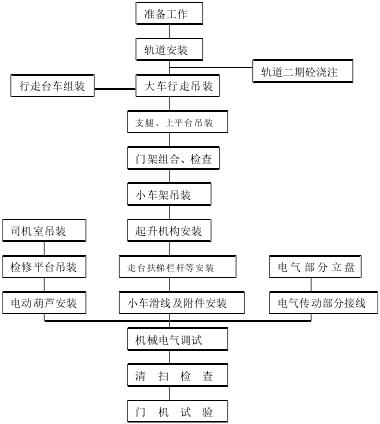

Two way door machine door machine installation in accordance with the established installation process, see the next page "Daxing power plant 2x250kN two-way door hoist" installation flow chart.

2, the specific construction process

The installation preparation.

A prepare the manufacturer's installation instructions and design drawings, prepare the necessary equipment and tools.

*0.5 (b) in the entrance of the accident gate of the 1# power station, 4 meters away from the center of the track, the distance of the center of the gate slot is about 4.3 meters, and the floor plate is embedded in the center of the track, the specification is about 0.5 meters.

2x250kN two-way gate hoist installation flow chart

C) the crest elevation of 470.60 meters to install all the debris in the plane of clean station.

D) heavy lifting lug lug before welding, installation of the actual delivery situation, such as manufacturers have set the manufacturers can use lug lug construction, leg lifting, welding in the leg top down 1 meters at the installation platform.

The cart track installation

According to the track gauge to measure the elevation and put on the line, when installing the rail surface inclination of rail surface shall not exceed the width of the 2.5/1000, after the installation of the central line of the rail line is not greater than + 2mm, otherwise not allowed to track and straightening, along axis distortion.

The main installation

The door machine is installed in the track two after the concrete strength reaches 80%.

(a) lower beam installation:

Door crane walking mechanism and beam in the whole assembly assembly after delivery, the weight of 6172.0kg, using the 70t truck crane located on the track at 470.60 elevation level, adjust the beam height, leg connected with the surface flatness and the angular error, after passing the appropriate reinforcement. The two ends of retaining reinforcement, beam bottom with stirrup form materials with I-beam or channel.

Leg support (B):

The lower beam after installation, the installation work of legs, legs and a weight 6450.9kg, using the 70t truck crane using the dipping on the lower beam, lifting the single rope symmetrical lug lug, the specific position in accordance with the construction drawings calculation of center of gravity is determined, ensure the legs under the plane level. The leg is connected with the lower crossbeam by bolts and connecting bolts to wear tight fastening, using electric wrench tightening torque according to the related standards. After the leg is installed, the flatness, height and diagonal error of the upper flange surface are detected. Reinforced by steel with double screw form, end is welded with the leg end and the base plate by welding, double screw can be adjusted to support the verticality of the legs.

Installation of platform on C):

Installation of upper platform after leg installation. Before lifting at 470.60 elevation 11 meters distance crane station center position on the platform and adjust the welding lug, the upper platform and the ground with sleeper support. The lifting lug position of the upper platform is arranged symmetrically at both ends of the two central lines, and the lifting lugs are processed according to the force of not less than 10 tons.

The platform weight reached 20t, divided into two sections each section of lifting 10t.

On the lifting platform with 1 70t auto crane, hoisting wire rope with 6 * 37+FC- 32 wire rope, long 6m, a total of 4 roots; shackle selection 10t.

Wire rope force calculation: F=G*2820/4/2733=2.6 t (G 10 t).

6 * 37+FC- 22 wire rope breaking force is 30.2 T, the safety coefficient is n=30.2/2.6=11.6>5, the wire rope hoisting shackle to meet the requirements; 10 t>2.6 T, but also to meet the requirements.

The choice of 1 70t truck crane hoisting hoisting crane, working radius is 11m, the crane arm is extended to 36 meters, the condition of the crane rated lifting weight is 12.5t, per day on the platform 10.1t, the hoisting crane load condition for rated load is 80.8%, can meet the requirements of crane lifting capacity.

After the lifting of the position, the measurement of various sizes, after the support leg and the upper part of the connection spot weld reinforcement.

After the platform is reinforced, the crane is loose, the position and deformation of the platform are measured, and the welding of the welded joints is carried out after the size is qualified. Welding installation platform is arranged on the top of the leg, the platform staff should fasten the safety belt mounting welding, and the safety rope on the legs, will the safety belt on the safety rope, to ensure the safety of high-altitude operation personnel.

D) car installation:

Lifting car factory assembled overall delivery to the site, after assembling the overall weight is 11008kg, installed by 70t automobile hoists the lifting platform to track, lug is arranged in the four corners of the frame (such as small manufacturers have welding lug lug manufacturers can use application, lifting crane) with 6 * 37 +FC- with 32 wire rope.